Instruments and Electrical

Welcome to our dedicated page for instruments and electrical solutions, where precision meets reliability. Explore our comprehensive range of essential industrial components designed to monitor, control, and optimize critical processes. From pressure and temperature sensors to flow meters, level indicators, valves & fittings, actuators, positioners, analyzers, motors, and PLC systems, our products are engineered to enhance operational efficiency and ensure seamless performance across various industries.

Discover how these advanced technologies can empower your operations in sectors such as manufacturing, oil & gas, pharmaceuticals, and beyond. Each product is meticulously selected and tested to meet stringent quality standards, providing you with the confidence to achieve excellence in your applications.

Pressure

Pressure is the force exerted per unit area by a fluid (liquid or gas) on a surface. It is a critical parameter in various industries, affecting processes and equipment performance. Measured in units such as pascals (Pa), bar, or psi, pressure control is essential for safety and efficiency.

A pressure transmitter is a device that converts pressure measurements into an electrical signal. Used in industrial applications, it helps monitor and control pressure in systems like pipelines, tanks, and HVAC systems, ensuring optimal performance and safety.

Differential Pressure Transmitter:

A differential pressure transmitter measures the difference in pressure between two points. It is commonly used in filtration, flow measurement, and level detection applications, providing accurate data for process control and monitoring.

Diaphragm Pressure Transmitter:

This type of pressure transmitter uses a diaphragm to sense pressure. It is ideal for measuring low pressures and is often used in applications where the process media may be corrosive or viscous, such as in chemical processing and food industries.

Etc.:

Other pressure transmitters include piezoelectric, capacitive, and resonant types, each suited for specific applications and offering different advantages in terms of accuracy, range, and environmental resistance.

Pressure Gauge:

A pressure gauge is an instrument used to measure and display the pressure of a fluid within a system. It is widely used in various industries to ensure systems operate within safe and optimal pressure ranges, with types including analog and digital gauges.

Differential Pressure Gauge:

This gauge measures the difference in pressure between two points within a system. It is essential in applications such as monitoring filter conditions, measuring fluid levels, and ensuring proper airflow in HVAC systems.

Bourdon Tube Pressure Gauge:

A Bourdon tube pressure gauge uses a curved tube that straightens when pressure is applied. It is a common and reliable type of mechanical gauge used in various industries to measure medium to high pressures accurately.

Digital Pressure Gauge:

Digital pressure gauges provide precise pressure readings displayed on an electronic screen. They offer higher accuracy, easy readability, and often include features like data logging and connectivity for remote monitoring.

Test Gauge:

A test gauge is a high-accuracy pressure gauge used for calibration and testing purposes. It ensures the accuracy of other pressure measuring instruments and is crucial in quality control and maintenance processes.

Etc.:

Additional pressure gauges include diaphragm, bellows, and capsule gauges, each designed for specific pressure ranges and applications, ensuring accurate measurement and monitoring in diverse environments.

A pressure switch is a device that opens or closes an electrical contact when a certain pressure level is reached. It is used for safety and control in systems such as pumps, compressors, and HVAC units, providing automatic response to pressure changes.

Temperature

Temperature is a measure of the thermal energy or heat present in a substance or environment. It indicates how hot or cold an object is and is a fundamental parameter in various scientific and industrial processes. Temperature control and measurement are essential for ensuring the proper functioning of equipment, safety, and efficiency in applications ranging from climate control to chemical reactions. Common units of temperature measurement include Celsius (°C), Fahrenheit (°F), and Kelvin (K).

A temperature transmitter converts temperature measurements from sensors (like RTDs or thermocouples) into an electrical signal. It is used in industrial applications to monitor and control processes, ensuring consistent temperature management and operational safety.

Differential Temperature Transmitter:

This device measures the difference in temperature between two points. It is used in applications such as HVAC systems, energy management, and process control to monitor temperature gradients and ensure efficient operation.

A temperature gauge is an instrument that measures and displays the temperature of a system or environment. Commonly used in industrial and commercial settings, it provides easy-to-read temperature data to maintain proper operating conditions.

Differential Temperature Gauge:

A differential temperature gauge measures the difference in temperature between two locations. It is used to monitor thermal efficiency and performance in systems like heat exchangers, ensuring optimal energy use and process control.

A temperature switch is a device that activates or deactivates an electrical circuit when a specified temperature is reached. It is used in applications such as thermostats, overheat protection, and process control to automate responses to temperature changes.

Thermometers are devices used to measure temperature. They come in various types, including liquid-in-glass, digital, infrared, and bimetallic strip thermometers, each suitable for different applications and offering various levels of accuracy and response time.

Thermocouples are temperature sensors made of two different metals joined at one end. They produce a voltage proportional to temperature differences, widely used in industrial applications for their broad range and fast response time.

Temperature sensors detect and measure temperature changes. Types include thermocouples, RTDs, thermistors, and infrared sensors, each offering specific advantages in terms of range, accuracy, and response time for various applications.

Flow

Flow refers to the movement of a fluid (liquid or gas) from one place to another, usually within a conduit like a pipe or channel. The flow rate measures the volume or mass of fluid passing through a cross-section of the conduit per unit of time, typically expressed in units like liters per second (L/s), cubic meters per hour (m³/h), or gallons per minute (GPM). Accurate flow measurement and control are vital in numerous industries, including water treatment, oil and gas, chemical processing, and HVAC systems, ensuring process efficiency, safety, and product quality.

A variable area flow meter, or rotameter, measures the flow rate of liquids and gases. It consists of a tapered tube and a float; as flow increases, the float rises, indicating the flow rate on a calibrated scale. It’s widely used for its simplicity and reliability.

A flow indicator is a device that provides a visual indication of fluid flow through a pipe. It can be as simple as a sight glass or more complex with moving parts like impellers, helping operators confirm that fluid is moving through the system.

An ultrasonic flow meter uses ultrasonic waves to measure fluid flow. It can be a transit-time type, where the travel time of the ultrasound is measured, or a Doppler type, which measures the frequency shift. It is non-intrusive and suitable for measuring clean or dirty fluids.

A mass flow meter measures the mass flow rate of a fluid passing through a tube. It provides direct measurement of mass flow, regardless of temperature and pressure changes, and is commonly used in applications requiring precise flow measurements, such as in the chemical and pharmaceutical industries.

A vortex flow meter measures fluid flow by detecting the vortices shed by a bluff body placed in the flow path. The frequency of vortex shedding is proportional to the flow rate, making it suitable for measuring the flow of liquids, gases, and steam in various industrial applications.

A flow switch monitors the flow of liquid or gas and activates an electrical switch when a set flow rate is reached. It is used for system protection, control, and monitoring, ensuring that flow rates stay within desired ranges and triggering alarms or system responses when necessary.

Level

Level refers to the height or amount of a substance (typically liquid or bulk solid) within a container, tank, or vessel. Accurate level measurement is crucial in various industrial processes to ensure safety, avoid overflow, and maintain efficient operation. Levels can be monitored and controlled using various methods and devices, depending on the application and the properties of the material being measured.

A magnetic level indicator uses a float with a magnet inside a chamber attached to the outside of a tank. As the fluid level changes, the float moves, causing a magnetic indicator to rise or fall along a calibrated scale, providing a clear, visual representation of the liquid level. It is often used in applications requiring reliable, non-invasive level monitoring.

A capacitance level transmitter measures the level of a liquid or solid by detecting changes in capacitance caused by the presence or absence of the material. The transmitter consists of a probe and an electronic circuit, and it is suitable for continuous level measurement in various industries, including chemicals, pharmaceuticals, and food processing.

An ultrasonic level transmitter uses ultrasonic waves to measure the distance between the sensor and the surface of the material. It calculates the level based on the time it takes for the waves to travel to the surface and back. This non-contact method is ideal for measuring the level of liquids and solids in applications where direct contact with the material is undesirable.

A level switch is a device that detects the presence or absence of a material at a specific level within a container and activates an electrical switch. It is used for controlling pumps, alarms, and other equipment to maintain the desired level. There are various types of level switches, including float, capacitance, and vibrating fork.

A float level switch uses a buoyant float that moves with the liquid level. The movement of the float opens or closes an electrical contact, triggering an action such as stopping a pump or sounding an alarm. Float level switches are simple, reliable, and widely used in water and wastewater treatment, industrial processes, and HVAC systems.

A level transmitter provides continuous level measurement by converting the level of a material into an electronic signal. Various technologies, such as ultrasonic, radar, capacitance, and hydrostatic pressure, can be used. Level transmitters are essential in industries requiring precise level control, such as oil and gas, chemical processing, and food and beverage production.

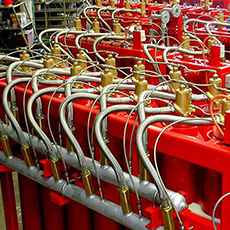

Valve & Fitting

Valves and fittings are crucial components in piping systems, controlling the flow and pressure of fluids (liquids, gases, and slurries). They ensure the safe and efficient operation of processes in various industries, including oil and gas, water treatment, chemical processing, and HVAC.

A safety valve automatically releases pressure from a system when it exceeds a preset limit to prevent equipment damage or catastrophic failure. It is essential in boilers, pressure vessels, and pipelines to ensure operational safety and regulatory compliance.

A diaphragm valve uses a flexible diaphragm to control fluid flow. It is ideal for applications requiring clean or sterile conditions, such as pharmaceuticals and food processing, as it isolates the fluid from the valve’s moving parts.

A plug valve uses a cylindrical or tapered plug to control fluid flow. The plug has a hole through it, and rotating the plug aligns the hole with the flow path or blocks it. Plug valves are used for quick, reliable shutoff in various industrial applications.

On/Off valves are used to start or stop the flow of fluids in a system. These valves, including ball valves, gate valves, and butterfly valves, provide a simple and efficient way to control flow with a straightforward open or closed position.

Regulating valves control the flow rate, pressure, or temperature of a fluid in a system. These valves, such as globe valves and control valves, are used in applications requiring precise flow regulation to maintain process stability and efficiency.

Solenoid valves use an electromagnetic solenoid to control fluid flow. When energized, the solenoid moves a plunger to open or close the valve. Solenoid valves are widely used in automated systems, offering quick and reliable control.

A needle valve has a small, tapered needle-like plunger that precisely controls fluid flow. It is used for fine adjustments in low-flow applications, such as instrumentation and laboratory equipment, providing accurate and consistent flow control.

A ball valve uses a spherical ball with a hole through it to control fluid flow. Rotating the ball 90 degrees opens or closes the valve. Ball valves are known for their durability, reliability, and excellent sealing properties, suitable for various applications.

A manifold is a device that connects multiple valves to a common chamber. 2, 3, and 5-way manifolds allow for the distribution and control of fluids from multiple sources or to multiple destinations, commonly used in instrumentation and process control.

A snubber protects pressure gauges and other sensitive equipment from sudden pressure spikes and surges. It dampens the impact of rapid pressure changes, extending the lifespan of the instrumentation and ensuring accurate readings.

Actuators

Actuators are devices that convert energy into mechanical motion to control systems and mechanisms. They are used in various applications, including industrial automation, robotics, and vehicle systems, enabling precise control of movement and positioning.

Hydraulic actuators use pressurized hydraulic fluid to produce motion. They are known for their high force and torque capabilities, making them ideal for heavy-duty applications such as construction equipment, manufacturing machinery, and aerospace systems.

Pneumatic actuators use compressed air to generate motion. They are widely used in automation and control systems for their speed, simplicity, and reliability. Common applications include industrial valves, material handling, and robotics.

Electric actuators use electrical energy to create motion. They provide precise control and are used in a variety of applications, including automation systems, HVAC controls, and automotive components. They come in various types, such as linear, rotary, and stepper actuators.

Thermal actuators use temperature changes to produce motion, typically through the expansion or contraction of materials. Magnetic actuators use magnetic fields to generate force. Both types are used in specialized applications, such as thermal protection devices and magnetic levitation systems.

Mechanical actuators convert one type of mechanical motion into another, such as converting rotational motion to linear motion. They include devices like gears, cams, and levers, used in a wide range of mechanical systems for precise movement control.

Other types of actuators include piezoelectric, which uses electric charge to induce mechanical strain, and electrohydraulic, which combines electric and hydraulic principles for high precision and force. Each type offers unique advantages for specific applications.

Positioners

Positioners are devices used to accurately control the position of valves or other mechanical components in industrial processes. They ensure precise positioning based on input signals, improving process efficiency and accuracy.

A pneumatic positioner uses compressed air to adjust and maintain the position of a valve or actuator. It receives control signals and modulates air pressure to achieve the desired valve position, commonly used in pneumatic control systems.

An electronic positioner uses electronic signals, such as 4-20 mA current loops or digital signals, to control valve position. It offers precise positioning and feedback capabilities, suitable for applications requiring high accuracy and automation.

Other types of positioners include electro-pneumatic positioners, which combine electronic control with pneumatic actuation for enhanced performance and flexibility in industrial automation. Each type of positioner offers specific features and benefits tailored to different process control needs.

Analyzers

Analyzers are instruments used to measure and analyze specific properties or components of substances, such as gases, liquids, or solids, in industrial and laboratory settings. They provide critical data for process monitoring, quality control, and environmental compliance.

An oxygen analyzer measures the concentration of oxygen in a gas mixture. It is used in various applications, including combustion control, medical oxygen monitoring, and environmental monitoring, ensuring safe and efficient operation.

A moisture analyzer measures the moisture content in gases, liquids, or solids. It is crucial in industries such as food processing, pharmaceuticals, and plastics, where precise moisture control is essential for product quality and performance.

Gas analyzers measure the composition and concentration of gases in a sample. They are used in environmental monitoring, industrial processes, and research to ensure safety, optimize production, and comply with regulatory requirements.

Water analyzers measure parameters such as pH, conductivity, turbidity, and dissolved oxygen in water samples. They are essential in water treatment plants, environmental monitoring, and laboratories to ensure water quality and safety.

Gas chromatographs separate and analyze components in a gas sample, providing detailed information about chemical composition. Online analyzers continuously monitor gases in real-time, offering immediate feedback for process control and optimization.

An automated analyzer performs analysis automatically, requiring minimal human intervention. It is used in high-throughput laboratories and industrial settings for rapid and consistent testing of samples, improving efficiency and reliability.

Other types of analyzers include spectrophotometers, mass spectrometers, and particle counters, each designed for specific analytical tasks and offering advanced capabilities for precise measurement and analysis in diverse applications.

Motors

Motors are devices that convert electrical energy into mechanical energy, producing rotational motion to drive machinery and equipment in various industrial, commercial, and residential applications.

AC (Alternating Current) motors operate on AC electrical power. They are widely used due to their reliability, simplicity, and ability to control speed and torque. AC motors include induction motors, synchronous motors, and various specialized types for specific applications.

DC (Direct Current) motors operate on DC electrical power. They are known for their precise speed control, high starting torque, and efficiency. DC motors are used in applications requiring variable speed and precise motion control, such as robotics, electric vehicles, and industrial automation.

High voltage motors operate at voltages higher than standard industrial voltages, typically above 1000 volts. They are used in applications where high power output is required, such as large industrial machinery, pumps, compressors, and generators.

Low voltage motors operate at standard industrial voltages, typically 600 volts or less. They are versatile and used in a wide range of applications, including fans, conveyors, machine tools, and HVAC systems, providing efficient and reliable operation.

An explosion-proof motor is designed to prevent the ignition of flammable gases or vapors surrounding the motor. They are essential in hazardous environments such as chemical plants, oil refineries, and mining operations, ensuring safety and compliance with regulations.

Other types of motors include servo motors, stepper motors, brushless DC motors, and gear motors, each offering specific features and benefits for different applications ranging from precision positioning to high torque operations.

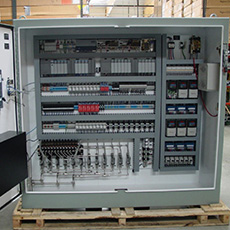

PLC (Programmable Logic Controller)

PLCs are industrial computers used to automate processes and control machinery. They are programmable and can monitor inputs and control outputs based on logic and sequencing instructions. PLCs come in single units for standalone applications or modular units for scalable and complex systems.

A PLC is a ruggedized digital computer used for automation of electromechanical processes. It is programmable and designed to operate in industrial environments, performing control functions such as logic operations, sequence control, timing, counting, and arithmetic computations.

Single unit PLCs are standalone controllers that integrate the CPU (Central Processing Unit), input/output modules, and programming interface into a single compact unit. They are suitable for small-scale applications where space and simplicity are priorities. Single unit PLCs are often used in standalone machines, simple control systems, and small manufacturing processes.

Modular PLCs consist of separate components that can be customized and expanded based on application requirements. They typically include a rack or chassis that holds various modules such as CPU modules, input/output modules (I/O modules), communication modules, and power supplies. Modular PLCs offer flexibility for complex control systems, allowing users to add or replace modules as needed without replacing the entire controller.

PLCs come in various configurations and sizes to suit different applications, from compact controllers for individual machines to large-scale systems controlling entire manufacturing plants. They are essential in industrial automation for improving efficiency, reliability, and flexibility in production processes.

DCSs are control systems used to manage complex processes across multiple locations. They distribute control functions among several controllers connected by a communication network, enabling centralized monitoring and control of industrial processes.

ESD systems automatically shut down processes in emergencies to prevent accidents, protect equipment, and ensure safety. They detect abnormal conditions, such as excessive pressure or temperature, and initiate emergency shutdown procedures.

F&G systems detect and respond to fire and gas leaks in industrial environments. They include sensors to monitor for flames, smoke, and hazardous gases, triggering alarms and initiating safety protocols to protect personnel and assets.

These controllers manage electrical and pneumatic systems, respectively, regulating power distribution and controlling pneumatic actuators and valves in industrial automation applications.

Flow computers measure and calculate the flow rate and total volume of gases and liquids in pipelines and industrial processes. They provide accurate flow data for monitoring, control, and billing purposes.

Transducers convert one form of energy or signal into another. In industrial applications, they often convert physical quantities such as pressure, temperature, or flow into electrical signals for measurement and control purposes.

Converters change the characteristics of electrical signals, such as voltage, current, or frequency, to match specific requirements of devices or systems in industrial automation and control.

Relays are electrically operated switches used to control high-power circuits with low-power control signals. They isolate control signals from high-voltage circuits, providing safety and reliability in industrial control systems.

Switches are devices used to control the flow of electrical power or signals within a circuit. They include various types such as push buttons, toggle switches, and limit switches, each serving specific control and safety functions.

Pressure regulators control and stabilize pressure in pneumatic or hydraulic systems. They maintain a consistent output pressure regardless of fluctuations in input pressure or flow rate, ensuring smooth operation of equipment.

A back pressure regulator controls the pressure upstream of a system to maintain a desired pressure downstream. It is used in applications such as reactors, pumps, and relief valve bypasses to control flow and prevent overpressure.

Flow indicators visually indicate the presence or movement of fluid in a pipeline or system. They provide operators with real-time visual confirmation of flow status, aiding in troubleshooting and process monitoring.

Instrument fittings and tubes connect components in fluid and gas systems, ensuring leak-tight connections and facilitating the installation and maintenance of instruments such as valves, gauges, and transmitters.

A digital process controller monitors and controls variables such as temperature, pressure, or flow in industrial processes. It receives input signals from sensors, calculates control actions, and sends output signals to actuators or control devices.

Transformers change the voltage level of alternating current (AC) electricity for distribution and use in industrial and commercial applications. They step up or step down voltage levels to match equipment requirements and ensure safe operation.

UPS systems provide backup power to critical equipment in case of mains power failure. They ensure continuous operation and protect against power disturbances such as surges, sags, and outages in industrial and data center applications.

Circuit breakers protect electrical circuits from overloads and short circuits by automatically disconnecting power when excessive current flows. They prevent damage to equipment and ensure electrical safety in industrial and residential installations.

Switchboards distribute electrical power from transformers and generators to various circuits and equipment in industrial facilities. They house circuit breakers, switches, and meters for power distribution and control.